This comprehensive guide explores IoT in Manufacturing, the technological backbone of Industry 4.0’s Smart Factory. We detail the core architecture, 12 key applications with measurable impacts (including predictive maintenance and digital twins), and provide a step-by-step implementation roadmap for CTOs and operations leaders.

Contents

Toggle1. The Dawn of the Connected Factory

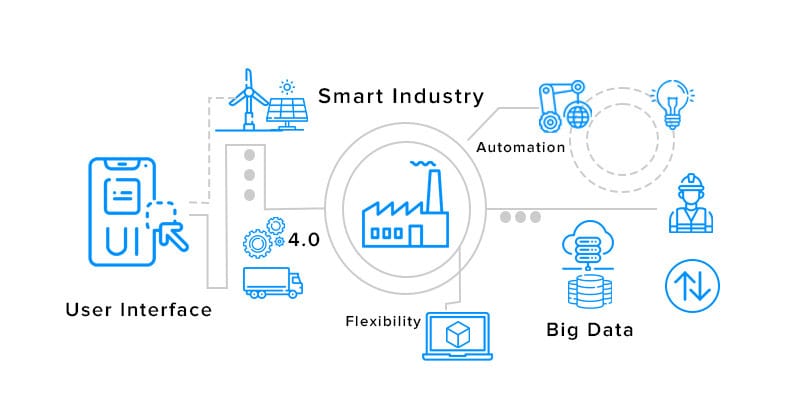

The manufacturing sector is undergoing its most significant transformation since the dawn of the computer. The traditional factory—a collection of siloed machines, manual processes, and reactive maintenance schedules—is being reimagined as a smart, connected, and intelligent ecosystem. This revolution, known as Industry 4.0, is powered by the Internet of Things (IoT) in manufacturing. By embedding sensors, actuators, and connectivity into every facet of the production floor, from individual components to complex robotic arms, manufacturers are unlocking unprecedented levels of operational visibility, efficiency, and agility. This is not a futuristic concept; it is the new competitive baseline.

The shift is from a system of isolated assets to a fully integrated cyber-physical network where data flows seamlessly from the factory floor to the cloud and back. This constant stream of real-time information, when analyzed with artificial intelligence (AI), allows for predictive insights, autonomous decision-making, and adaptive control over the entire production value chain. The economic impact is undeniable. Market analysts project the global IoT in manufacturing market to exceed USD 400 billion by 2030, driven by the pursuit of tangible business outcomes. Today’s forward-thinking manufacturers are leveraging IoT not just to cut costs, but to build more resilient supply chains, enhance worker safety, achieve sustainability goals by optimizing energy consumption, and respond to market demands with unparalleled speed. The Smart Factory is no longer an abstract ideal; it is the data-driven backbone of modern industrial competitiveness.

2. Core Architecture of IoT in Manufacturing

A successful IoT implementation in a manufacturing environment relies on a robust and scalable architecture that can handle data from thousands of endpoints, process it in real time, and deliver actionable insights. This architecture must not only support new, smart devices but also integrate seamlessly with decades of legacy operational technology (OT) systems like Manufacturing Execution Systems (MES), SCADA, and Enterprise Resource Planning (ERP) systems. The goal is to create a unified data fabric that eliminates silos and provides a single source of truth.

A typical Industrial IoT (IIoT) architecture is structured in four distinct layers, each serving a critical function in the data journey from the physical world to the business application.

Key Components of the IIoT Stack:

Smart Sensors & Actuators: These are the nerve endings of the smart factory. Sensors collect data on parameters like temperature, vibration, pressure, location, and chemical composition. Actuators receive commands to perform physical actions, such as adjusting a valve, changing a robot’s speed, or shutting down a machine.

Connectivity & Edge Computing: Data from sensors is transmitted using a mix of wired and wireless protocols. OPC UA (Open Platform Communications Unified Architecture) is a critical standard for secure and reliable data exchange between machines. For real-time processing, edge computing is essential. Edge gateways process data locally, enabling sub-second responses for critical tasks and reducing the volume of data sent to the cloud. The rollout of 5G promises to enhance this capability with ultra-low latency and massive bandwidth. MQTT (Message Queuing Telemetry Transport) is a lightweight messaging protocol often used to efficiently transmit data from the edge to the cloud.

Cloud Platform (IaaS/PaaS): The cloud serves as the central hub for data storage, large-scale analytics, and application hosting. It offers virtually limitless scalability to handle data from multiple factories. Here, massive datasets are stored in data lakes, processed, and fed into AI and machine learning models to identify patterns and generate predictive insights.

AI Analytics & Visualization: This is where raw data is transformed into business value. Machine learning algorithms analyze historical and real-time data to power applications like predictive maintenance and quality control. Visualization dashboards (e.g., Grafana, Power BI) present these insights through intuitive charts, graphs, and digital maps, giving plant managers and executives a clear view of operational performance.

The 4-Layer Architecture:

Device Layer (Perception): This layer consists of the physical assets—the machines, sensors, robots, and PLCs on the factory floor that generate the data.

Edge Layer (Gateway & Local Processing): Edge gateways aggregate data from the device layer, perform initial filtering and analysis, and execute real-time control logic. This layer is crucial for reducing latency and ensuring operational continuity even if cloud connectivity is lost.

Cloud Layer (Global Processing & Analytics): This central platform ingests data from the edge, stores it, and runs complex, computationally intensive AI models. It provides the “big picture” view across the entire enterprise.

Application Layer (UI/UX): This is the user-facing layer, comprising the dashboards, mobile apps, and enterprise system integrations (ERP, MES) that present data and insights to human operators and decision-makers.

A well-designed architecture built on open standards ensures interoperability and prevents vendor lock-in, allowing a manufacturer to create a scalable ecosystem that can grow and adapt across a global network of factories.

3. Key IoT + AI Applications in Manufacturing

The convergence of IoT and AI is unlocking a host of transformative applications that redefine what is possible on the factory floor. These solutions move beyond simple data collection to create a predictive, self-optimizing, and highly efficient production environment. Below are 12 critical applications that form the foundation of the modern Smart Factory.

Smart Factory — The Intelligent Backbone of Industry 4.0

What It Is: A Smart Factory is a fully connected and flexible manufacturing environment where physical production processes and operations are optimized through digital technology, real-time data, and AI-driven insights. It represents the complete integration of all the applications listed below into a cohesive, intelligent system.

How It Works: It leverages a network of IoT sensors to collect data from every machine, production line, and worker. This data is analyzed in real time by AI platforms to automate workflows, predict failures, optimize resource allocation, and provide decision-makers with a comprehensive, live view of the entire manufacturing operation.

Key Benefits: Enhanced agility to respond to market changes, significant improvements in operational efficiency (OEE), and the creation of a resilient, data-driven production ecosystem.

Example & Measurable Impact: A leading automotive manufacturer integrated its assembly line with an IoT platform, connecting over 1,000 robotic arms and welding stations. By analyzing the data, they optimized production workflows and implemented predictive maintenance, resulting in a 20% increase in overall productivity and a 15% reduction in unplanned downtime across the plant.

Predictive Maintenance with IoT + AI

What It Is: Predictive Maintenance (PdM) is a proactive strategy that uses real-time data and AI to predict when a piece of equipment is likely to fail, so that maintenance can be performed just in time to prevent the failure.

How It Works: IoT sensors are placed on critical machinery to monitor key health indicators like vibration, temperature, and power consumption. AI models, trained on historical failure data, analyze these live data streams to detect subtle anomalies that precede a breakdown. When the model predicts a high probability of failure, it automatically generates a work order in the Computerized Maintenance Management System (CMMS).

Key Benefits: Drastically reduces unplanned downtime, extends the lifespan of machinery, and lowers maintenance costs by moving away from fixed schedules.

Example & Measurable Impact: A global CPG company deployed vibration and temperature sensors on its packaging line motors. The AI-powered PdM system they implemented led to a 40% reduction in unplanned machine downtime and a 25% decrease in annual maintenance costs. Learn more about building a predictive analytics solution

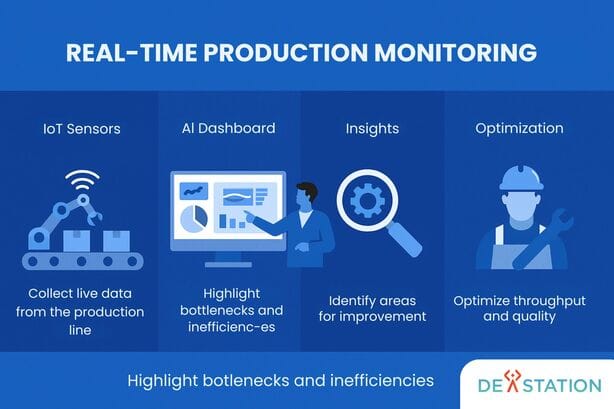

Real-Time Production Monitoring

What It Is: This involves using IoT sensors to continuously track the performance of production lines and measure key performance indicators (KPIs) like Overall Equipment Effectiveness (OEE), throughput, and cycle time in real time.

How It Works: Sensors on conveyor belts, CNC machines, and assembly stations feed data into a central dashboard. This provides plant managers with a live, granular view of the factory floor, allowing them to instantly identify bottlenecks, track production targets, and respond to issues as they happen.

Key Benefits: Improves visibility into production efficiency, enables faster root cause analysis of delays, and empowers operators with the data they need to meet targets.

Example & Measurable Impact: A steel manufacturer installed IoT sensors on its rolling mills to monitor speed, temperature, and output. The real-time dashboard allowed them to identify and resolve micro-stoppages, leading to a 10% improvement in OEE within six months.

Digital Twin for Manufacturing

What It Is: A Digital Twin is a dynamic, virtual replica of a physical asset, process, or entire factory. It is continuously updated with real-time data from its physical counterpart, creating a highly accurate simulation model.

How It Works: Data from IoT sensors is fed into a sophisticated physics-based model of the asset. This allows engineers and operators to run “what-if” scenarios, test new process parameters in a virtual environment without risking physical production, and visualize the impact of changes.

Key Benefits: Accelerates product design and commissioning, optimizes production processes in a risk-free environment, and provides a powerful tool for training operators.

Example & Measurable Impact: An aerospace company created a digital twin of its engine assembly line. Before implementing a new robotic cell, they simulated the entire workflow, identifying a critical bottleneck that would have caused significant delays. This virtual commissioning process reduced the physical setup time by 30%. Explore our Digital Twin solutions

Quality Control with AI Vision

What It Is: This application uses high-resolution cameras and AI-powered computer vision models to automate the inspection of products on the assembly line, identifying defects that are often invisible to the human eye.

How It Works: As products move along a conveyor, cameras capture images that are fed into a trained deep learning model. The model analyzes each image in milliseconds to detect scratches, cracks, misalignments, or other quality issues. Defective products are automatically flagged or removed from the line.

Key Benefits: Increases defect detection rates, improves first-pass yield, reduces the cost of manual inspection, and ensures consistent product quality.

Example & Measurable Impact: An electronics manufacturer deployed an AI vision system to inspect circuit boards. The system achieved a 99.9% defect detection accuracy, compared to 92% with human inspectors, and increased the production line’s throughput by 12%.

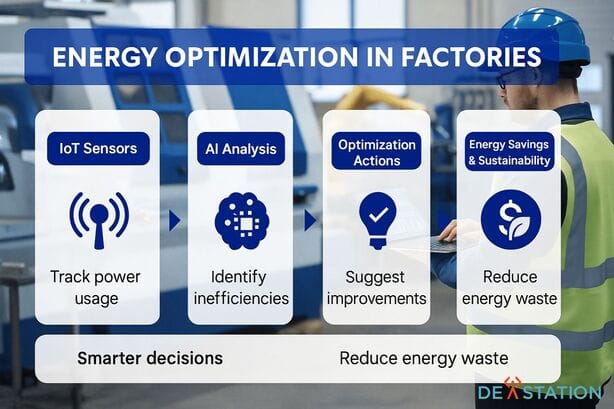

Energy Optimization in Factories

What It Is: This involves using IoT sensors and smart meters to monitor energy consumption across the factory in real time and leveraging AI to identify opportunities for reduction.

How It Works: Sub-meters are installed on high-consumption machinery, HVAC systems, and lighting circuits. The data is aggregated on a central platform, which visualizes consumption patterns. AI algorithms can then identify wastage, such as machines left idling, and can automate systems to power down when not in use or adjust operation to take advantage of lower off-peak energy tariffs.

Key Benefits: Reduces operational costs, helps meet corporate sustainability and ESG goals, and lowers the factory’s carbon footprint.

Example & Measurable Impact: A heavy manufacturing plant implemented an IoT-based energy management system. By identifying and eliminating inefficiencies, they achieved a 15% reduction in overall energy consumption, translating to over $500,000 in annual savings.

Supply Chain & Inventory Management

What It Is: IoT in manufacturing extends beyond the factory walls to provide real-time visibility into the supply chain, from raw material delivery to finished goods distribution.

How It Works: RFID tags and GPS trackers are placed on containers, pallets, and high-value components. This allows for real-time tracking of inventory both within the warehouse and in transit. Automated systems can trigger re-orders when stock levels fall below a certain threshold, ensuring a lean, just-in-time logistics flow.

Key Benefits: Prevents stock-outs, reduces carrying costs, improves forecast accuracy, and provides end-to-end visibility into the supply chain.

Example & Measurable Impact: A food and beverage company used IoT sensors to track the temperature and location of its perishable goods in transit. This real-time monitoring reduced spoilage by 25% and improved on-time delivery rates.

Worker Safety & Smart Wearables

What It Is: This application uses wearable IoT devices—such as smart helmets, connected vests, and wristbands—to monitor worker safety and environmental conditions in real time.

How It Works: Wearables can detect if a worker has had a fall, enters a restricted high-risk zone (geofencing), or is exposed to harmful gases. The devices can send automatic alerts to supervisors. They can also be used to ensure that only certified operators are using specific heavy machinery.

Key Benefits: Dramatically improves worker safety, reduces workplace accidents, and helps ensure compliance with safety regulations like OSHA.

Example & Measurable Impact: A construction materials company equipped its lone workers with GPS-enabled wearables featuring a panic button and fall detection. This led to a 60% faster emergency response time and a measurable improvement in employee safety ratings.

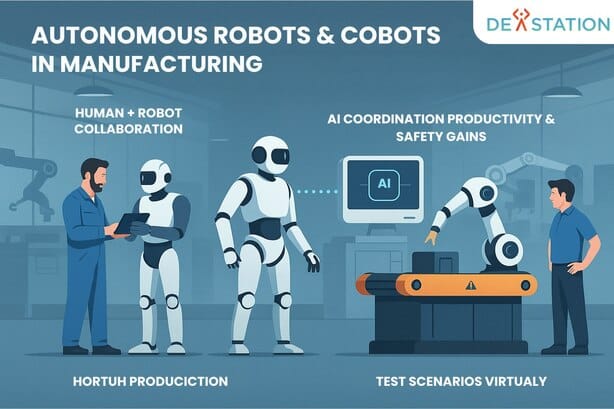

Autonomous Robots & Cobots

What It Is: IoT provides the connectivity and data streams that enable autonomous mobile robots (AMRs) and collaborative robots (cobots) to operate intelligently on the factory floor.

How It Works: AMRs use IoT-connected sensors (like LiDAR) to navigate the factory, moving materials from the warehouse to the assembly line without human intervention. Cobots work alongside human operators, using sensors to ensure they operate safely and can be easily programmed to perform tasks like picking, placing, and assembly.

Key Benefits: Automates repetitive material handling tasks, increases production flexibility, and improves ergonomic conditions for human workers by taking over strenuous tasks.

Example & Measurable Impact: An e-commerce fulfillment center deployed a fleet of 200 AMRs to manage its warehouse. The robots increased order picking efficiency by over 300% and allowed the company to handle a 50% increase in order volume without adding staff.

AI-Driven Process Optimization

What It Is: This goes beyond simple monitoring to use AI to actively recommend or implement changes to production parameters to maximize output and minimize waste.

How It Works: AI models analyze data from hundreds of sensors across a production line (e.g., temperature, pressure, speed, raw material composition). The model learns the complex relationships between these variables and can recommend optimal settings to increase throughput, improve yield, or reduce energy per unit produced.

Key Benefits: Moves from a reactive to a proactive and optimized production model, continuously improving efficiency and product quality.

Example & Measurable Impact: A chemical processing plant used an AI model to analyze its reactor parameters. The model’s real-time recommendations for temperature and pressure adjustments resulted in a 5% increase in chemical yield and a 7% reduction in energy consumption.

Cybersecurity in Smart Manufacturing

What It Is: This involves implementing robust security measures to protect the converged IT and OT networks of a smart factory from cyber threats.

How It Works: Security for IoT in manufacturing requires a multi-layered approach. This includes network segmentation to isolate critical machinery, continuous threat monitoring of OT traffic for anomalous behavior, secure device provisioning to ensure only authorized devices can connect, and regular security patching.

Key Benefits: Protects intellectual property, prevents operational disruptions caused by cyberattacks, and ensures the safety of workers and equipment.

Example & Measurable Impact: After a near-miss with a ransomware attack, a major industrial manufacturer partnered with a cybersecurity firm to implement an OT monitoring solution. The system now detects and quarantines over 99% of threats before they can impact production.

From Factory to Market — End-to-End Visibility

What It Is: This application connects the real-time data from the factory floor with the broader supply chain and market demand signals, creating a truly demand-driven production model.

How It Works: By integrating IoT data with ERP and SCM systems, manufacturers can gain full traceability of a product from its raw material origins to the end customer. This allows them to respond quickly to changes in customer orders, adjust production schedules dynamically, and provide customers with accurate delivery timelines.

Key Benefits: Increases supply chain resilience, enables mass customization, and improves customer satisfaction through enhanced transparency.

Example & Measurable Impact: A high-fashion apparel company uses RFID tags on its products, linking production data to its e-commerce platform. This end-to-end visibility allows them to quickly shift production based on which styles are selling best online, reducing overstock by 30%.

4. Implementation Roadmap: From PoC to Full-Scale Smart Factory

Adopting IoT in manufacturing is a strategic journey, not a one-time project. A phased approach is critical to manage risk, demonstrate value, and ensure successful enterprise-wide adoption.

A 4-Phase Roadmap for Success:

Phase 1: Strategy & Use Case Definition: Begin by identifying the most significant business challenges that IoT can solve. Focus on a specific, high-impact problem, such as unplanned downtime on a critical production line or excessive energy consumption. Define clear, measurable success metrics (e.g., “reduce downtime by 15% on Line A”).

Phase 2: Proof of Concept (PoC): Start small. Select a limited number of machines or a single process for a PoC. The goal is to test the technology, validate its effectiveness in your environment, and confirm the potential ROI. A successful PoC builds momentum and secures stakeholder buy-in for further investment.

Phase 3: Pilot Deployment: After a successful PoC, expand the solution to an entire production line or a specific area of the factory. This pilot phase is used to refine the architecture, address integration challenges with legacy systems, and train the first group of operators and maintenance staff.

Phase 4: Scale Company-Wide: Once the pilot has proven to be stable, scalable, and value-generating, develop a blueprint for rolling out the solution across other production lines, or even other factories in your network. This is where the true enterprise-level benefits of standardization and data aggregation are realized.

Common Challenges and Recommended Solutions:

| Challenge | Recommended Solution |

| Integration Complexity | Prioritize solutions built on open standards (OPC UA, MQTT). Use an experienced system integrator to bridge legacy OT systems with modern IT platforms. |

| Cybersecurity Risks | Implement a “security-by-design” approach from the start. Segment OT and IT networks and deploy continuous threat monitoring tools for the factory floor. |

| Data Overload & Complexity | Utilize edge computing to pre-process data locally. Partner with data science experts to build effective AI models and ensure you are collecting the right data, not just all the data. |

| Unclear ROI | Start with a use case that has a clear, quantifiable business impact, such as predictive maintenance or energy savings. Track metrics rigorously from the PoC phase. |

| Talent & Skills Gap | Invest in upskilling your existing workforce. Partner with an external expert who can provide training and managed services while your internal team builds its capabilities. |

By following this structured roadmap and proactively addressing these common challenges, manufacturers can navigate the complexities of digital transformation and build a truly intelligent factory.

5. Future Outlook: Beyond Industry 4.0

The evolution of the smart factory is far from over. As technology continues to advance, the capabilities of IoT in manufacturing will expand into new frontiers, paving the way for even more autonomous and intelligent industrial ecosystems. Several key trends are shaping this future.

Edge AI is set to become mainstream, where complex machine learning models run directly on edge gateways or even on the devices themselves. This will enable even faster, more sophisticated real-time decision-making without reliance on the cloud, which is critical for applications like robotic control and high-speed quality inspection. The emergence of 6G will provide the near-instantaneous, high-bandwidth connectivity required to support massive deployments of these intelligent edge devices.

Digital Twin 2.0 will evolve from being a mere replica to a fully autonomous agent. These next-generation twins will not only simulate processes but will also use reinforcement learning to independently discover new, more efficient ways of operating, constantly self-optimizing the physical factory for performance and energy consumption. This leads to the concept of the self-optimizing factory, where multi-agent AI systems manage production schedules, supply chain logistics, and maintenance autonomously.

Looking further ahead, these trends are building towards Industry 5.0. This next wave of industrial transformation places a renewed focus on the collaboration between humans and machines. It is defined by three core pillars: being human-centric (using technology to empower, not replace, workers), sustainable (driving circular economy and environmental goals), and resilient (creating adaptive and agile supply chains). In this vision, the smart factory is not just efficient; it is an intelligent, sustainable, and collaborative partner in creating value.

6. Conclusion: The Inevitable Shift to Intelligent Production

The integration of IoT and AI is not merely an incremental improvement for the manufacturing industry; it is a fundamental paradigm shift. The Smart Factory, powered by real-time data and predictive insights, represents the essential backbone of Industry 4.0 and the future of industrial competitiveness. By moving from reactive problem-solving to proactive, data-driven optimization, manufacturers can achieve dramatic improvements in efficiency, quality, and sustainability.

Applications like predictive maintenance, AI-powered quality control, and digital twins are already delivering measurable ROI for early adopters, proving that this transformation is both practical and profitable. The ability to connect the factory floor to the entire value chain creates a level of visibility and agility that is impossible to achieve with traditional systems, enabling the predictive, adaptive, and resilient production models required to thrive in a volatile global market. The journey to a fully autonomous, self-optimizing factory is underway, and the companies that embrace this technological evolution will be the industrial leaders of the next generation, paving the way for the human-centric and sustainable promise of Industry 5.0.

7. Build Your Smart Factory with Dev Station Technology

The transition to a smart factory requires a partner with deep expertise in both operational technology and modern IT infrastructure. Dev Station Technology helps manufacturers integrate IoT, AI, and cloud into their production ecosystem—delivering predictive maintenance, energy optimization, and smart monitoring systems that drive measurable ROI. We bridge the gap between your legacy machinery and the intelligent cloud, creating a seamless data pipeline that turns factory-floor information into your most valuable strategic asset.

Our services are designed to guide you through every stage of your Industry 4.0 journey, including:

IoT system design & device integration (OPC UA, MQTT)

AI-powered analytics & computer vision platforms

Digital Twin & predictive maintenance solutions

Scalable cloud and edge architecture deployment

We deliver end-to-end solutions that are secure, scalable, and tailored to your unique operational goals.

🚀 Ready to modernize your factory? Contact Dev Station Technology today for a free consultation to explore how our IoT and AI solutions can transform your production environment.

Schedule a consultation → https://dev-station.tech/contact/

Or email us directly: sale@dev-station.tech